The Project

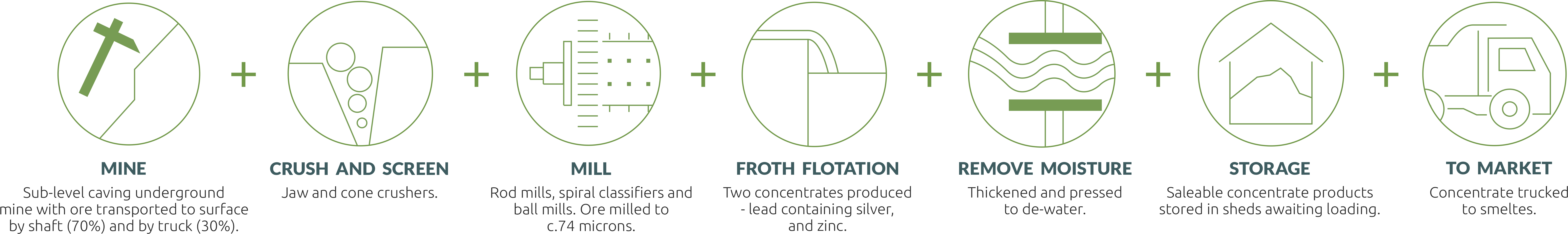

How we produce zinc and lead

Sasa is an underground zinc and lead mine that produces around 800,000 tonnes of ore each year.

The mine has three main areas:

Svinja Reka, Kozja Reka, and Golema Reka.

Currently, only Svinja Reka is being mined, accessed through tunnels from the surface.

The mining process involves drilling, blasting, and excavating the ore. Since 2023, the Sasa team is transitioning to new mining methods called cut and fill stoping (C&F) and long-hole stoping (LHS) with paste backfill, that provide better support for the excavations.

After blasting, most of the ore is transported via rail wagons, while the rest is hauled to the surface by trucks. On the surface, the ore is crushed and milled to prepare it for flotation, a process that separates the lead and zinc.

The resulting lead and zinc concentrates are then filtered and prepared for sale to smelters. The lead concentrate typically contains about 73% lead, and the zinc concentrate contains about 49% zinc.

INVESTING IN THE MINE

SASA IS CURRENTLY TRANSITIONING TO NEW MINING METHODS TO CREATE A SAFER AND MORE SUSTAINABLE UNDERGROUND MINING OPERATION FOR THE LONG TERM

Construction of a Paste Backfill Plant and associated reticulation pipes

Construction of a Dry Stack Tailings Plant and preparation of an associated landform

Development of a new, wider and direct-access decline known as the Central Decline

The purpose of the investments is to:

• Facilitate the transition of Svinja Reka’s mining method from sub-level caving (SLC) to a combination of SLC, cut and fill stoping (C&F) and long-hole stoping (LHS).

• Maximise the extraction of the underground resources at Sasa by utilising paste backfill to improve the geotechnical characteristics of the mine and more selective mining methods.

• Create a safer and more sustainable underground mining operation whilst also extending the life of mine (LOM).

• Reduce the environmental footprint by ensuring that Sasa does not have to build and operate another downstream tailings facility following TSF4 during its life of mine to 2039. Instead, tailings will be stored on the new dry stack tailings facility or utilised as as paste backfill underground.

• Allow CAML to set a target of 70% of Sasa’s life of mine material waste being stored in a more environmentally responsible manner by the end of 2026 and a long-term target of 75% reduction in surface water abstraction by the end of 2026.